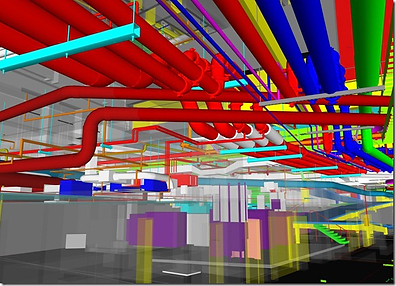

BIM-Based MEP Coordination

The difficulties associated with the conventional coordination process of Mechanical, Electrical, and Plumbing (MEP) systems have resulted in extensive efforts to enhance the process through utilization of BIM technology. The overarching objective of this study was to capture the underpinnings of BIM-based coordination process as currently practiced by AEC firms in the U.S. It was found out that number of clashes resolved in each meeting, BIM competency of team members, and number of trades attending meetings were identified as the most commonly collected information items by AEC firms throughout the MEP coordination process. Team experience level, preliminary design quality, and MEP system complexity were found as the most important factors that impact the MEP coordination process. Several best practices were recommend by participants in this study to improve the efficiency of MEP coordination process. These strategies were described under the four different phases of an MEP project: initiation and planning, 3D modeling, MEP coordination, and construction and installation. The findings of this research will help AEC firms by describing information requirements for establishing a procedure to track, measure, and compare MEP coordination progress across different construction projects.